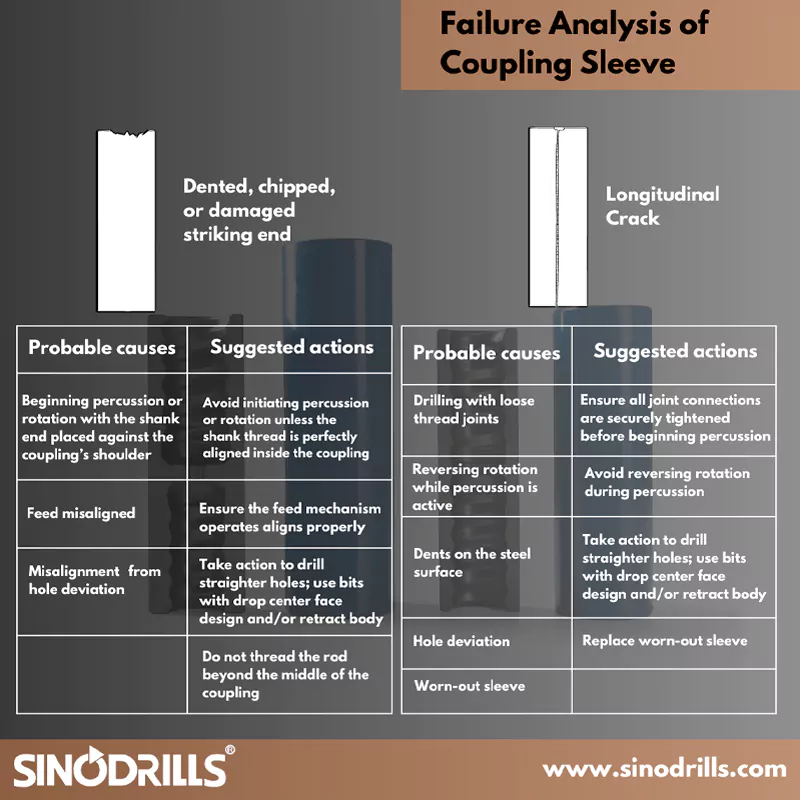

1. Dented, chipped, or damaged striking end

Probable causes:

– Beginning percussion or rotation with the shank end placed against the coupling’s shoulder

– Feed misaligned

– Misalignment from hole deviation

Suggested actions:

– Avoid initiating percussion or rotation unless the shank thread is perfectly aligned inside the coupling

-Ensure the feed mechanism operates aligns properly

-Take action to drill straighter holes; use bits with drop center face design and/or retract body

-Do not thread the rod beyond the middle of the coupling

2. Longitudinal crack

Probable causes:

-Drilling with loose thread joints

-Reversing rotation while percussion is active

-Dents on the steel surface

-Hole deviation

-Worn-out sleeve

Suggested actions:

-Ensure all joint connections are securely tightened before beginning percussion

-Avoid reversing rotation during percussion

-Take action to drill straighter holes; use bits with drop center face design and/or retract body

-Replace worn-out sleeve

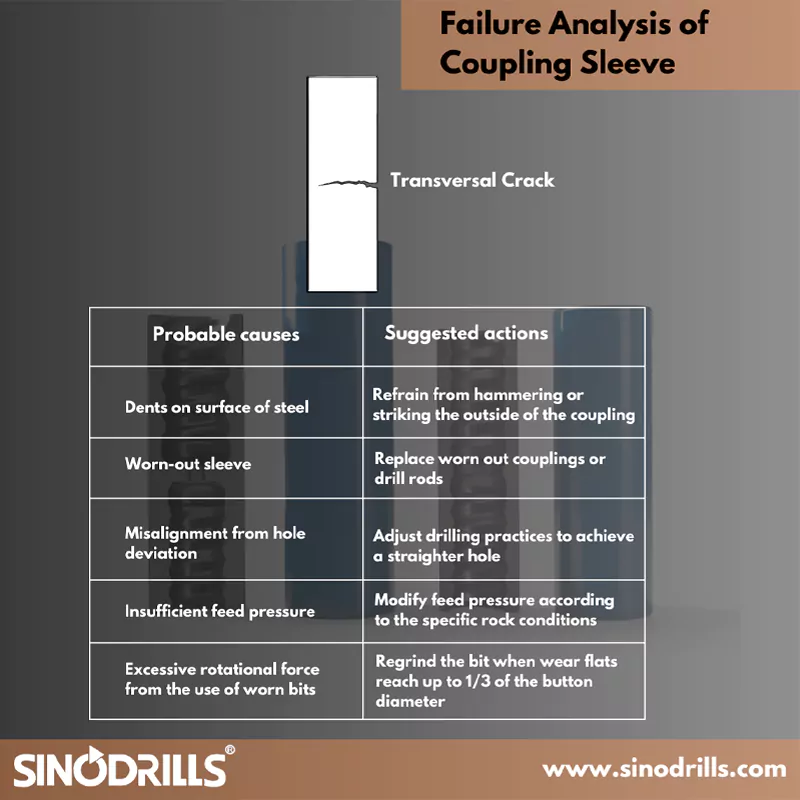

3. Transversal crack

Probable causes:

-Dents on surface of steel

-Worn-out sleeve

-Misalignment from hole deviation

-Insufficient feed pressure

-Excessive rotational force from the use of worn bits

-Thread mismatches

Suggested actions:

-Refrain from hammering or striking the outside of the coupling

-Replace worn out couplings or drill rods

-Adjust drilling practices to achieve a straighter hole

-Modify feed pressure according to the specific rock conditions

-Regrind the bit when wear flats reach up to 1/3 of the button diameter