Thread drill rods are essential components in precision drilling operations, yet they are prone to wear and failure under high stress. Understanding the factors that contribute to rod damage, including material defects, improper usage, and environmental conditions, is key to ensuring reliable performance and longer service life.

Failure analysis of thread drill rods helps manufacturers and users identify root causes of breakage or deformation. By studying patterns of wear, fractures, and surface defects, engineers can implement corrective measures, improve rod design, and optimize drilling processes to minimize downtime and increase operational efficiency.

What are Thread Drill Rods?

Recommended Drill Rods

Thread drill rods are essential components in drilling systems, designed to transmit rotational and axial forces from the drilling machine to the drill bit. They are typically made of high-strength steel or alloy materials to withstand extreme stress, torque, and impact during drilling operations in mining, construction, and geological exploration.

These rods feature precision-engineered threads at both ends, allowing them to connect securely with drill bits, couplers, or other rods. Their durability, straightness, and thread accuracy are critical for efficient drilling, consistent hole alignment, and preventing premature wear or failure, making them a vital part of any drilling operation.

8 Thread Drill Rod Failure Reasons

Thread drill rod failure is a common challenge in drilling operations, often resulting from wear, fatigue, or improper handling. Identifying the causes of failure is essential to prevent downtime, improve safety, and extend the lifespan of rods. Understanding failure patterns allows engineers to optimize material selection, maintenance practices, and drilling techniques effectively.

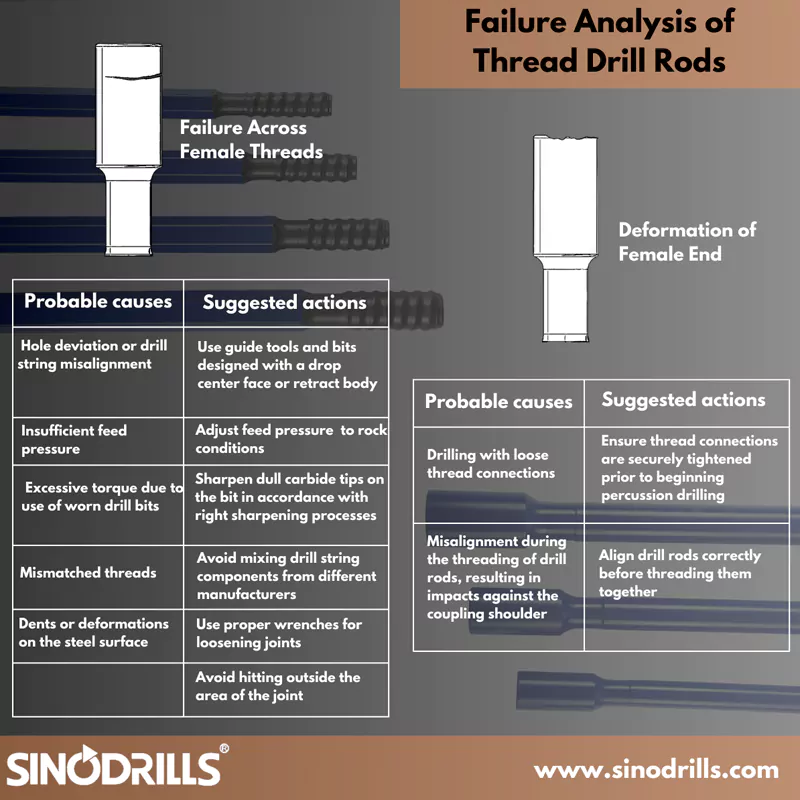

1. Failure Across Female Threads

Probable causes:

-Hole deviation or drill string misalignment

-Insufficient feed pressure

-Excessive torque due to use of worn drill bits

-Mismatched threads

-Dents or deformations on the steel surface

Suggested actions:

-Use guide tools and bits designed with a drop center face or retract body

-Adjust feed pressure based on the rock conditions

-Sharpen dull carbide tips on the bit in accordance with recognized sharpening processes

-Avoid mixing drill string components from different manufacturers

-Use proper wrenches for loosening joints

-Avoid hitting outside the area of the joint

2. Deformation of the female end

Probable causes:

-Drilling with loose thread connections

-Misalignment during the threading of drill rods, resulting in impacts against the coupling shoulder

Suggested actions:

-Ensure thread connections are securely tightened prior to beginning percussion drilling

-Align drill rods correctly before threading them together

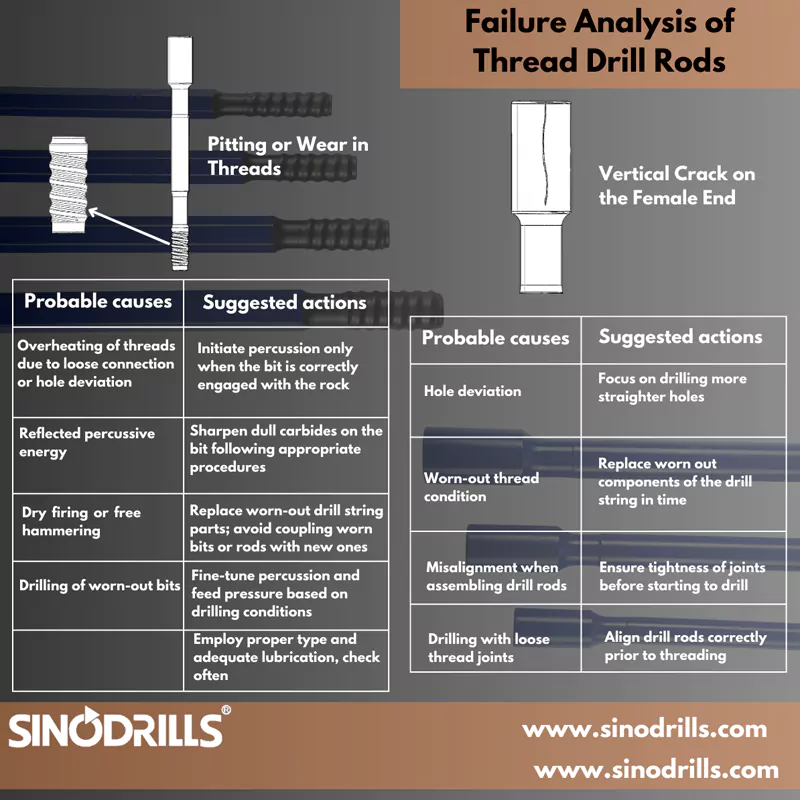

3. Vertical crack on the female end

Probable causes:

-Hole deviation

-Worn-out thread condition

-Misalignment when assembling drill rods

-Drilling with loose thread joints

Suggested actions:

-Focus on drilling more straighter holes

-Replace worn out components of the drill string in time

-Ensure tightness of joints before starting to drill

-Align drill rods correctly prior to threading

4. Pitting or Wear in Threads

Probable causes:

-Overheating of threads due to loose connection or hole deviation

-Reflected percussive energy

-Dry firing or free hammering

-Drilling of worn-out bits

Suggested actions:

-Initiate percussion only when the bit is correctly engaged with the rock

-Sharpen dull carbides on the bit following appropriate procedures

-Replace worn-out drill string parts; avoid coupling worn bits or rods with new ones

-Fine-tune percussion and feed pressure based on drilling conditions

-Employ proper type and adequate lubrication, check often

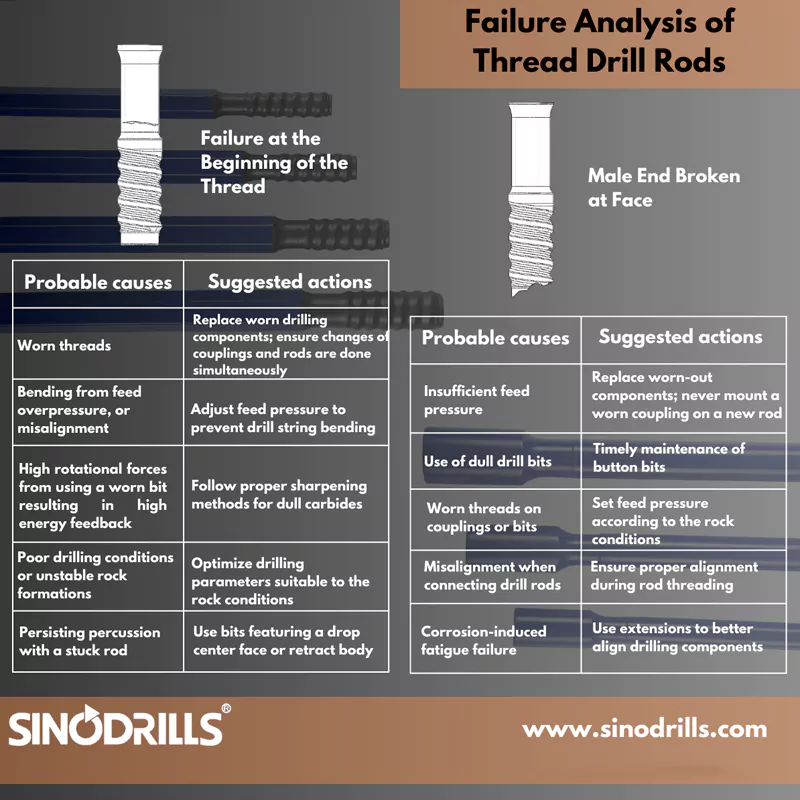

5. Failure at The Beginning of the Thread

Probable causes:

-Worn threads

-Bending from feed overpressure, or misalignment

-High rotational forces from using a worn bit resulting in high energy feedback

-Poor drilling conditions or unstable rock formations

-Persisting percussion with a stuck rod

-Bending due to poor alignment

Suggested actions:

-Replace worn drilling components; ensure changes of couplings and rods are done simultaneously

-Adjust feed pressure to prevent drill string bending

-Follow proper sharpening methods for dull carbides

-Optimize drilling parameters suitable to the rock conditions

-Use bits featuring a drop center face or retract body

-Avoid engaging percussion with a stuck drill string

6. Male end broken at the face

Probable causes:

-Insufficient feed pressure

-Use of dull drill bits

-Worn threads on couplings or bits

-Misalignment when connecting drill rods

-Corrosion-induced fatigue failure

Suggested actions:

-Replace worn-out components; never mount a worn coupling on a new rod

-Timely maintenance of button bits

-Set feed pressure according to the rock conditions

-Ensure proper alignment during rod threading

-Use extensions to better align drilling components

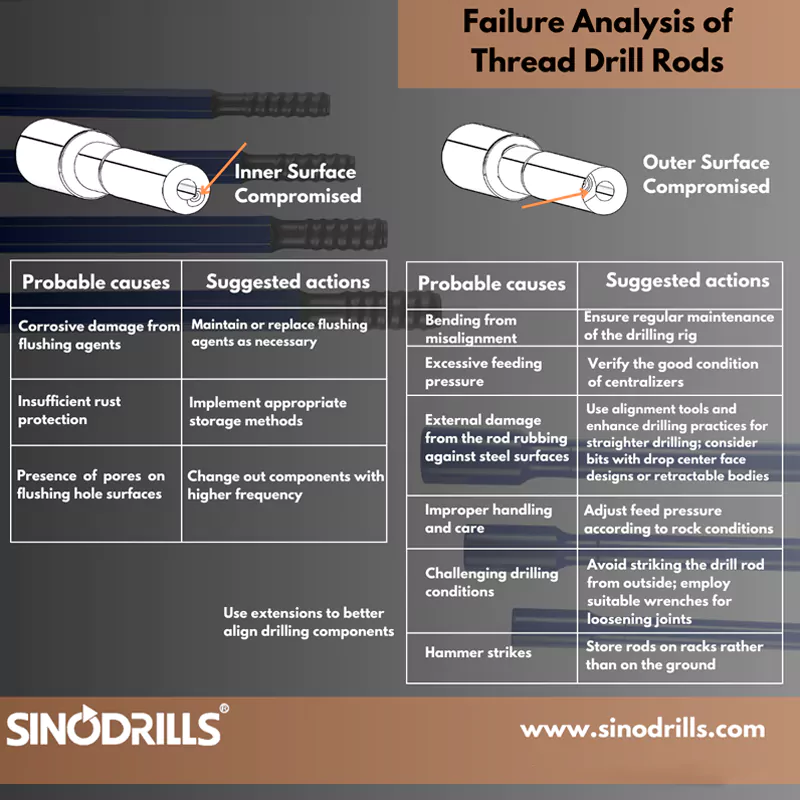

7. Inner surface compromised

Probable causes:

-Corrosive damage from flushing agents

-Insufficient rust protection

-Presence of pores on flushing hole surfaces

Suggested actions:

-Maintain or replace flushing agents as necessary

-Implement appropriate storage methods

-Change out components with higher frequency

8. Outer surface compromised

Probable causes:

-Bending from misalignment

-Excessive feeding pressure

-External damage from the rod rubbing against steel surfaces

-Improper handling and care

-Challenging drilling conditions

-Hammer strikes

Suggested actions:

-Ensure regular maintenance of the drilling rig

-Verify the good condition of centralizers

-Use alignment tools and enhance drilling practices for straighter drilling; consider bits with drop center face designs or retractable bodies

-Adjust feed pressure according to rock conditions

-Avoid striking the drill rod from outside; employ suitable wrenches for loosening joints

-Store rods on racks rather than on the ground;

-Adjust drilling parameters to rock conditions

How to Inspect Thread Drill Rod Failure

Inspecting thread drill rod failure is essential to identify the root causes and prevent recurrence. A careful examination of wear, fractures, and deformation patterns helps determine whether failure is due to material defects, operational errors, or environmental factors, improving overall drilling efficiency.

- Visual Inspection: Examine the rod for cracks, corrosion, or surface irregularities. Look for discoloration or pitting, which may indicate overheating or chemical damage. Early detection through visual checks prevents catastrophic failures and ensures rods are replaced before severe damage occurs.

- Dimensional Measurement: Measure rod diameter, thread pitch, and straightness. Deviations from specifications indicate wear, bending, or threading issues. Accurate measurements help identify areas under excessive stress, guiding maintenance schedules and reducing the risk of tool failure during drilling operations.

- Fracture Analysis: Study broken rod surfaces using magnification or microscopy. Patterns such as fatigue striations or brittle fractures reveal underlying causes like cyclic stress, improper material hardness, or impact damage. Understanding fracture types informs corrective actions to improve rod design and handling.

- Material Testing: Conduct hardness, tensile, or metallurgical tests. These assessments determine if the rod meets material specifications and can withstand operational stresses. Material inconsistencies or defects are often a primary cause of failure, making testing a critical part of inspection.

- Operational Review: Evaluate drilling procedures, torque, feed rate, and maintenance history. Misuse or overloading often accelerates wear. Reviewing operational data ensures that the rods are used correctly and helps implement training or process adjustments to extend service life.

What to Do with the Failed Thread Drill Rods?

When thread drill rods fail, proper handling and evaluation are essential to prevent repeated failures and optimize resources. Failed rods can offer insights into operational issues, material defects, and maintenance practices, helping improve future rod performance and extend service life.

- Analyze the Failure: Carefully examine the rod to identify the root cause. Look for wear patterns, cracks, or fractures. This analysis helps prevent similar failures in new rods and provides guidance for improving drilling procedures, material selection, and handling practices.

- Separate and Label: Clearly separate failed rods from usable stock and label them with failure type and inspection notes. This prevents accidental reuse, ensures safety, and maintains organized inventory management, making it easier for engineers to track recurring issues and take corrective action.

- Recycle or Repurpose: If the material is suitable, send failed rods for recycling or repurposing. Metal rods can often be melted and reused, reducing waste and cost. Some rods may be reshaped or used in less critical applications, extending their useful life.

- Update Maintenance Records: Record details of each failed rod, including inspection findings, operational conditions, and failure patterns. Proper documentation supports preventive maintenance strategies, helps in forecasting replacement needs, and improves decision-making for future purchases.

- Review Operational Practices: Use failure data to optimize drilling procedures, including torque, feed rate, and handling methods. Implementing process improvements based on real-world failures reduces the risk of recurrence and enhances the overall efficiency and lifespan of thread drill rods.

Conclusion

In summary, conducting a thorough failure analysis of thread drill rods is critical for maintaining drilling efficiency and preventing costly equipment downtime. Identifying the causes of wear, breakage, or deformation allows for better material selection, process optimization, and preventive maintenance.

Understanding failure patterns also aids in designing more durable rods and improving operational techniques. By addressing both internal material flaws and external usage conditions, businesses can significantly enhance the lifespan of their thread drill rods and reduce replacement costs.

For reliable performance and bulk supply, get wholesale thread drill rods from our Sinodrills. We provide high-quality, durable rods designed to withstand demanding drilling conditions, ensuring your projects run smoothly with minimal interruptions.