• Quick rates of installation by combining drilling, insertion and grouting in one single operation.

• Low-noise percussion drilling.

• No separate system installation, no casing and rod removal required. The drill bit remains in the ground serving as a spacer.

• Choice of drill bits for the most diverse ground conditions.

• Identical installation principle for all ground conditions and systems.

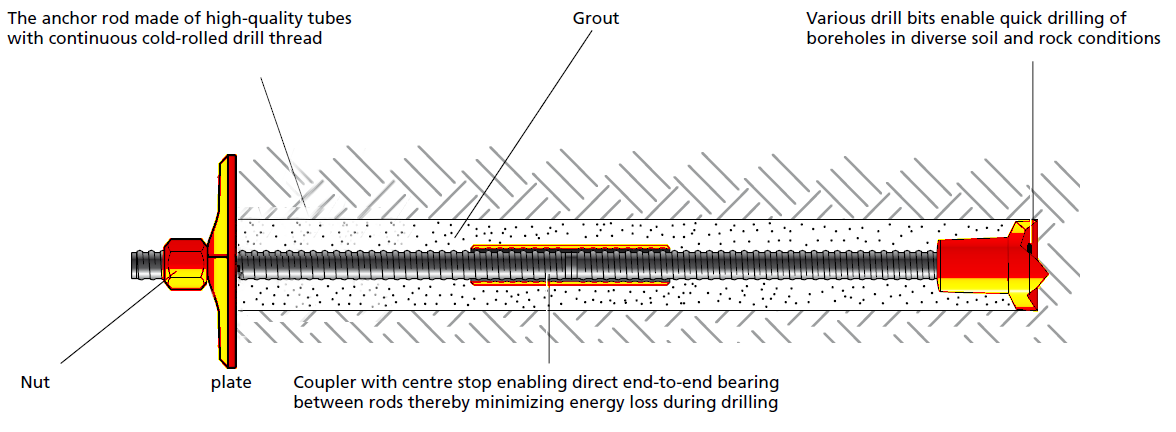

• The hollow core anchor rod serves not only to flush the borehole with air or water during drilling, but also to grout voids and to carry out high-pressure injections of the annular space.

• Choice of high-quality grouts and mixers.

• Flexibility in length by using couplers.

• Ability to work with small drill rigs without casing in narrow spaces.

• Enhanced corrosion protection.

• The high standard of QA systems consistently ensures high quality from production to installation of the injection anchors/piles.

• National and European approvals with CE marking.

• Drill bits of various diameters and types (as suitable for the respective ground).

• Hollow core anchor rods of various diameters with a continuous rolled left-hand thread and available in standard lengths of 1 m, 2 m, 3 m, 4 m and 6 m.

• Couplers to connect and extend the hollow core anchor rods, with center stop for enhanced energy transfer and sealing.

• Solid plates or domed plates for connection to the structure.

• Hexagonal nuts for anchoring and locking.