Installation Procedures of Self Drilling Anchor system

Self-drilling installation may be accomplished either manually or semi-automated, depending on the available drilling machinery.

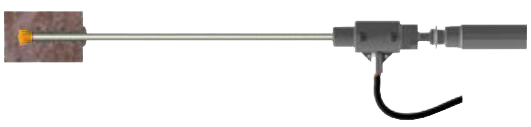

Simultaneous drilling and grouting

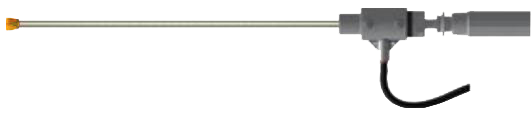

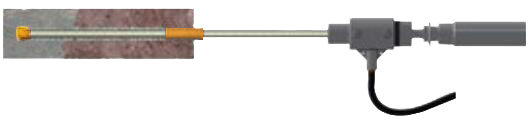

Assembly of the self drilling anchor bar and

self drilling anchor bit connected to the rotary injection adapter

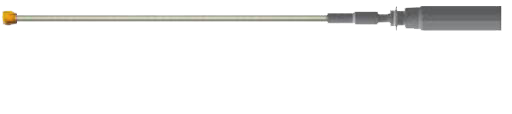

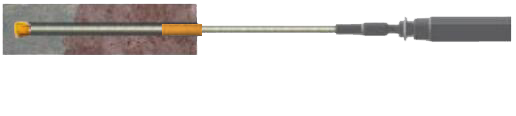

Assembly of the self drilling anchor bar

and self drilling anchor bit connected to the rock drill

Rotary self-drilling installation and simultaneous grouting

Rotary percussive self-drilling installation without casing:

Single-use drill bit and hollow bar drill steel, water or

air water mixture flushing

Optional extension using couplings

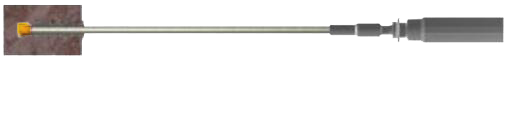

Optional extension using couplings

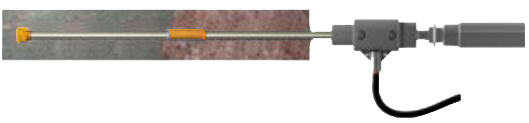

De-coupling from the rotary injection adapter

De-coupling from the drilling machinery,

subsequent grouting using a post-grouting adapter

Assembly of anchorage or head construction (plate and nut), depending on the application

Self-drilling installation and subsequent grouting

Main Advantages of Self Drilling Anchor system

• Simultaneous drilling and installation

• Installation using standard drilling machinery

• Immediate load-bearing capacity after installation and activation of the expansion element

• Reduction of cycle time due to the de-coupling of the grouting procedure from installation

• Ability to maintain load-bearing capacity even when undergoing large deformations

• Tough system components

• Safe, easy, and reproducible installation procedure

• Improved drilling accuracy thanks to the directional guidance of the self-drilling expansion element

• Trouble-free application in unstable borehole conditions

• Easy extension using couplings

• Design and diameter of the expansion element can be adjusted to suit different and varying ground conditions